Samsung SDS Deploys “AI-Powered Digital Logistics” to Counteract Global Supply Chain Risks

+ Leveraging AI to enable fast and accurate development of risk sensing-analysis-response strategy

+ Implementing hyperautomation in logistics through generative AI

+ Offering at-a-glance view of logistics data, ranging from real-time cargo volume to time, cost, and environmental impact

On May 20th, Samsung SDS held “Cello Square Media Day” at Samsung SDS Campus (Global Headquarter) to present an overview of its AI-powered digital logistics for counteracting global supply chain risks.

Since the COVID-19 pandemic, the global supply chain has suffered a series of disruptions including △ geopolitical risks stemming from Russia-Ukraine war and the Red Sea crisis, △ shifts in the global supply chain driven by protectionist measures of the U.S. and Europe, and △ climate response issues associated with climate change and carbon emission regulations.

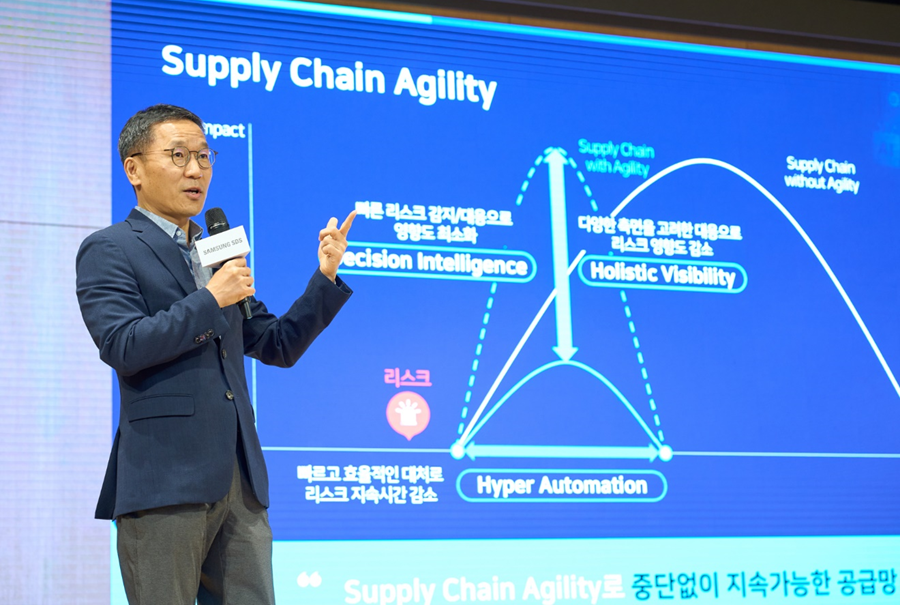

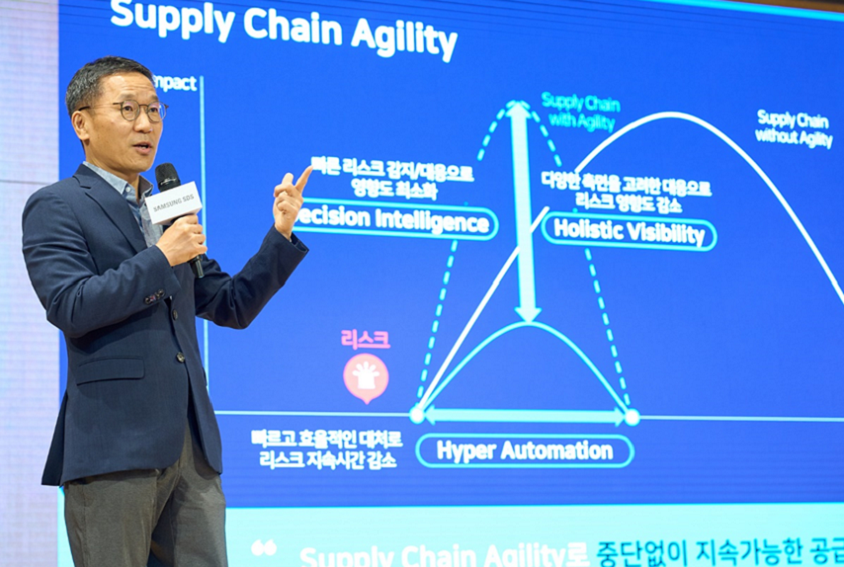

Samsung SDS highlighted that a digital transformation in logistics is essential to respond to the rapidly changing global landscape, and introduced measures to minimize the impact of global supply chain risks and their exemplary cases.

□ Leveraging AI for real-time risk sensing and swift response measures

Samsung SDS is deploying machine learning and generative AI to detect supply chain risks in real time and devise response strategies in a timely manner.

With machine learning, the company automatically extracts logistics risk data from more than 60,000 global news articles complied on a daily basis.

The company then applies generative AI to classify the risks into three levels depending on their severity. This has been enabled through the company’s development of a model gauging the degree of risk based on over 20,000 global logistics risk cases of the past, and training generative AI to assess the level of risks.

When the cargo likely to be affected by a risk is identified automatically, the company’s logistics experts swiftly devise a response plan based on data analysis and expertise. The time required for setting up the plan has also been shortened from one day to two hours, indicating a significant improvement in the speed of risk responses.

In fact, Samsung SDS was able to immediately detect the clash between Israel and Iran in April, and accordingly notified its customers on the impact on air cargo that was scheduled to arrive in Israel. Afterwards, to prepare against the escalation of the conflict, the company proposed an alternative transport route leveraging neighboring countries after shipping the affected cargo by sea to nearby ports in Oman and UAE, and ultimately succeeded in completing the shipment in time.

□ Implementing hyperautomation in logistics through generative AI

Samsung SDS is using generative AI to implement hyperautomation across the services and logistics operations of its customers.

Previously, customers had to click each menu to check their logistics information on Cello Square, the digital logistics platform of Samsung SDS. But now, they can easily enjoy the platform’s services including quotation and calculation of containers by simply talking to the generative AI.

Moreover, Samsung SDS is leveraging generative AI to automate simple, repetitive tasks in logistics operations. In the past, the person in charge had to respectively check cargo and settlement data by each customer, but the company is now enhancing the system so that cargo volume and cost data by each customer can be retrieved all at once solely by talking to the generative AI.

□ Improving visibility into logistics by factoring into time, cost, and environmental impact

Currently, Samsung SDS offers real-time information on cargo movement, vessel delays, port congestion, and container status on Cello Square.

Furthermore, the company provides predictive ETA data with an improved level of accuracy by estimating a vessel’s expected travel time and port stay duration based on analyses of past data.

It also forecasts abnormal situations such as occurrence of port docking fees or detention of vessels as well as sea and air freight rates to improve visibility into future costs.

In addition, the company is providing information on carbon emission volumes and carbon intensity by transportation mode including air, sea, land, and rail transport on Cello Square, while preparing various solutions for reducing carbon emissions to support the ESG management of its customers.

Kooil Oh, Executive Vice President and Leader of the Logistics Business Division of Samsung SDS, stated, “Due to global risks that have continuously emerged since COVID-19, the demand for digital transformation in logistics has increased among customers.” He added, “Leveraging digital technologies and AI, Samsung SDS will provide sustainable logistics services without disruption despite profound changes in the global supply chain.”

Meanwhile, Samsung SDS also held “Cello Square Conference 2024” on the same day of the Media Day event, which brought together various industry players including shippers, e-commerce sellers, and partner companies to share perspectives on changes in the global situation, market trends, and digital transformation solutions for addressing supply chain risks.