Nexplant Visual Insight

AI-powered intelligent visual data analytics platform specially designed for factory-generated image data analytics

Deploying a complex, sophisticated AI process is just one click away

- Accuracy rate to extract product faulty 98% on average

- Leakage rate of faulty products 330ppm or less

- Extract rate compared to that with naked eyes 3 times more Secured

Benefits

Meet AI-based video analysis intelligence platform specialized in manufacturing environment

-

Equipment Management for Hyper-connectivityNexplant VI easily transfers and shares data between cameras (vision, infrared thermal, CCTV, etc.), edge appliance and the visual analysis platform, and its equipment management feature helps you view the whole set of data at one glance.

Equipment Management for Hyper-connectivityNexplant VI easily transfers and shares data between cameras (vision, infrared thermal, CCTV, etc.), edge appliance and the visual analysis platform, and its equipment management feature helps you view the whole set of data at one glance.

Once model training is completed, the model can easily be deployed into edge appliance through UI. This significantly reduces the workload of system administrators. -

Optimized Infrastructure for Real-time, High-speed Operation & AnalysisGPU farm-based resource optimization minimizes the necessary server resources and enables real-time, high-speed computation of complicated operations. Its offering set of Nexplant VI with HW, servers and edge appliances will help you more flexibly respond to different site scales and environments. Infrastructure custom-built for an individual customer is also available.

Optimized Infrastructure for Real-time, High-speed Operation & AnalysisGPU farm-based resource optimization minimizes the necessary server resources and enables real-time, high-speed computation of complicated operations. Its offering set of Nexplant VI with HW, servers and edge appliances will help you more flexibly respond to different site scales and environments. Infrastructure custom-built for an individual customer is also available. -

High Performance, Accurate Analysis at Minimum CostNexplant VI reduces the time to develop analysis algorithms to the minimum level and empowers non-expert users to succeed in high performance modeling. It also helps the analysis system continuously maintain its operational reliability and accuracy.

High Performance, Accurate Analysis at Minimum CostNexplant VI reduces the time to develop analysis algorithms to the minimum level and empowers non-expert users to succeed in high performance modeling. It also helps the analysis system continuously maintain its operational reliability and accuracy.

Features

-

Easy AI Model Lifecycle Management

Non-expert users can develop and build AI-powered models easily, and maintain or further improve the model performance continuously with the easy-to-run AI Ops platform.

-

Refinement Features for Convenient Modeling

Enjoy Nexplant VI’s outstanding features – Visual Search, Auto Tagging, Image Refinement and Dataset Configuration while spending significantly less time on running the features and enhancing the model’s performance.

-

Special Features for Best Model Selection

Nexplant VI self-finds an optimal model most suitable for the data collected and makes model recommendations. It also features performance comparison of the trained models, making complicated modeling process simpler and easier.

-

Use of Edge Devices

Apply the edge computing technology for real-time, high-speed computation. This helps you spend less the network deployment cost and address latency issues for growing field data volumes.

-

Auto-analysis of Product Defects

Auto-analysis of high-resolution images helps you detect product defects and find root causes. You can get the improvement of the overall productivity by managing and controlling the process ahead of time.

-

Safety Management for Equipment and Facilities

Monitoring CCTV cameras automatically detect abnormal running of factory equipment and facilities in real time to proactively prevent safety incidents and keep the workplace safe.

-

Safety Management for Workers

Nexplant VI senses potentially dangerous situations that could arise at the workplace and sends instant alerts to ensure the safety of workers in real time. This will prevent workplace accidents and injuries and help stakeholders take immediate action.

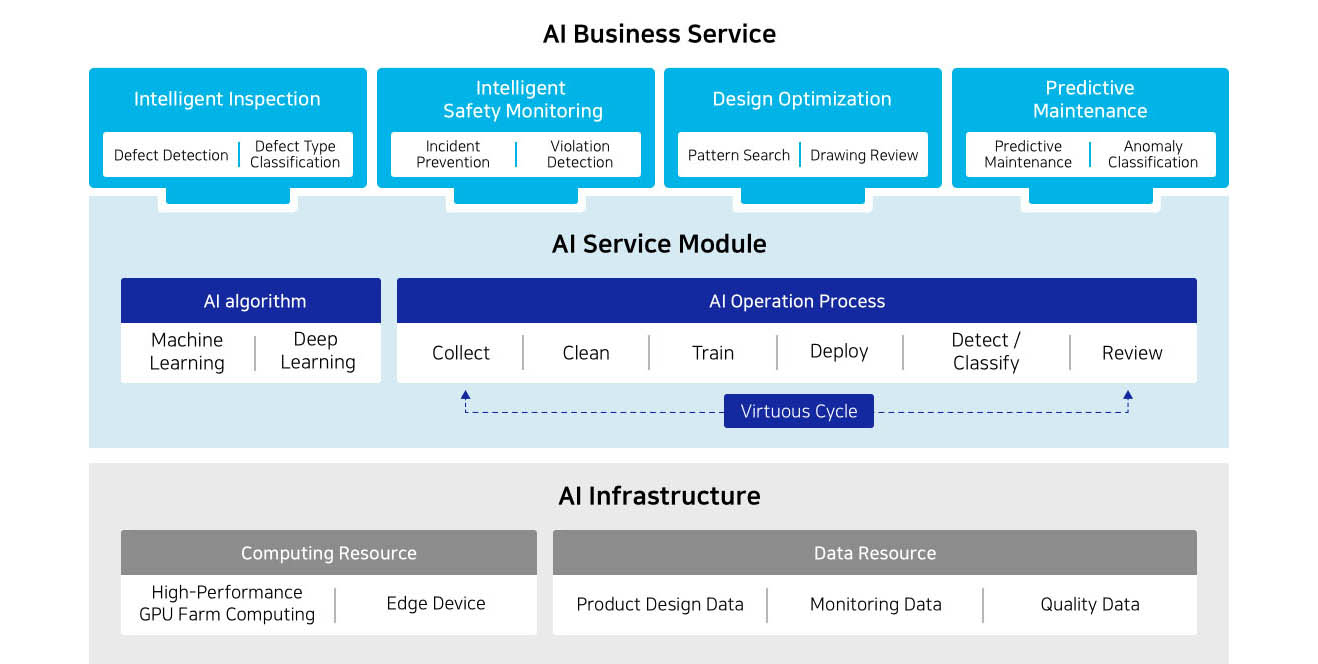

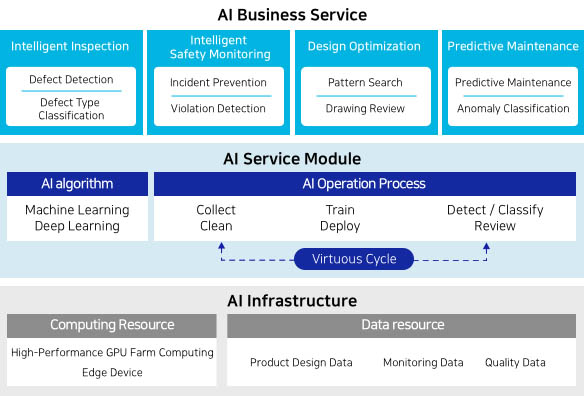

Platform Architecture

Nexplant Visual Insight Platform Architecture

- Intelligent Inspection - Defect Detection

- Intelligent Safety Monitoring - Incident Prevention, Violation Detection

- Design Optimization - Pattern Search, Drawing Review

- Predictive Maintenance - Predictive Maintenance, Anomaly Classification

- AI algorithm - Machine Learning, Deep Learning

- AI Operation Process - (Virtous Cycle) Collect, Clean, Train, Deploy, Decect/Classify, Review

- Computing Resource - High-Performance GPU Farm Computing, Edge Device

- Data Resource - Product Design Data, Monitoring Data, Quality Data

Use Cases

-

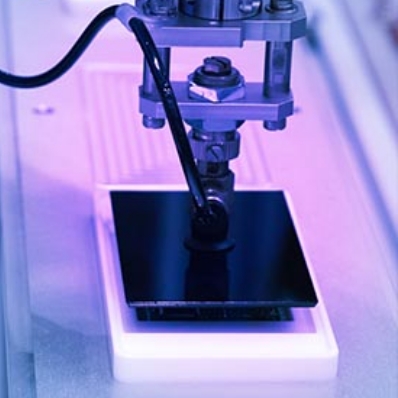

Surface Inspection ToolReal-time inspection of surface defects using the product’ surface images will significantly improve productivity.

Surface Inspection ToolReal-time inspection of surface defects using the product’ surface images will significantly improve productivity.

Apply it for quality inspection of vehicle painting, semiconductor wafer, mobile phones, bearings and other products of different sizes and materials. -

Equipment Anomaly Detection SystemComprehensive analysis of data collected from sensors and cameras including IR camera, CCTV and patrol robots detects abnormal signs in equipment and helps you take immediate action.

Equipment Anomaly Detection SystemComprehensive analysis of data collected from sensors and cameras including IR camera, CCTV and patrol robots detects abnormal signs in equipment and helps you take immediate action.

This enables a factory to spot equipment issues that need technicians’ attention ahead of time, prevent accidents and determine the best timing for parts replacement. -

Equipment Auto-Controller for Worker’s SafetyThe superior level of 3D tomography analysis using IRT Sensor clearly distinguishes the shape of a worker from that of adjacent objects, and senses worker’s entry to hazardous areas in real time to prevent safety incidents.

Equipment Auto-Controller for Worker’s SafetyThe superior level of 3D tomography analysis using IRT Sensor clearly distinguishes the shape of a worker from that of adjacent objects, and senses worker’s entry to hazardous areas in real time to prevent safety incidents. -

Safety Monitoring SystemThe system analyzes unusual signs detected at the site in real time and alerts the monitoring center so that necessary action can be taken immediately.

Safety Monitoring SystemThe system analyzes unusual signs detected at the site in real time and alerts the monitoring center so that necessary action can be taken immediately.

This will efficiently prevent EHS incidents at industrial sites and ensure business continuity. -

Edge Inspection DeviceThe integrated inspection device provides optimized set of edge devices and Nexplant VI platform to analyze a vast amount of data in real time and reduce network scaling cost.

Edge Inspection DeviceThe integrated inspection device provides optimized set of edge devices and Nexplant VI platform to analyze a vast amount of data in real time and reduce network scaling cost.

Specifications

-

HW(WEB/WAS)

– CPU: 2.1Ghz, 8cores or above

– Memory: 32GB or above

– Storage: 2TB or above -

HW(DB/Storage)

– CPU: 2.1Ghz, 4 cores or above

– Memory: 32GB or above

– Storage: 5TB or above -

HW (Training Server)

– CPU: 2.1Ghz, 8 cores or above

– Memory: 128GB or above

– GPU: V100 x 2

(※ If distributed, v100 x 4, Node (HW) 2 units (x2) or above)

– Storage: 2TB or above -

HW (Server for Proprietary Features)

(※ If Auto Tagging, BMP, Simulation, Image Search are included: HW x 2, If the Detection feature is added, HW x 3)

– CPU: 2.1Ghz, 8 cores or above

– Memory: 64GB or above

– GPU: V100 x 2

– Storage: 2TB or above -

HW (Decision Server)

– CPU: 2.1Ghz, 8 cores or above

– Memory: 64GB or above

– GPU: V100 x 1

– Storage: 1TB or above -

SW

– (WEB/WAS) Server OS: Linux-64bit

– User Agent Browser: Internet Explorer 11 or above

Related Offerings

Find out more about our offerings

Various services will be provided by freely utilizing 3D data from different devices. Users can realize innovation in work environments.

Nexplant PLM can provide efficient collaboration tools for project managers, which accelerates the product launching. By integrating the project development projects in the entire supply chain (e.g. OEM), every participants can be provided with the same information.

Product design and verification can be completed more swiftly through the auto-implementation of CAE and simulation analytics. As products become more complicated and processes more refined, such requirements can be dealt with through automation/optimization based on data while accelerating the production speed.

The most optimized automatic equipment control enables to quickly respond to sudden changes of products. While enhancing productivity and reducing downtime, the quality can be maintained at efficient costs.

The optimized management will be available throughout the entire life cycle of asset from purchaing factory equipment to operation, maintenance and discharging. By linking information real time and accurately analyzing the information, users can secure the predictability of the process and the transparency in the status of asset.

This is the most optimized solution that manages PCs on site in an integrated manner by controlling unauthorized software, blocking security threats, and deploying the central control of work systems.

Whether you’re looking for a specific business solution or just need some questions answered, we’re here to help